New Heavy duty 3axis CNC Router

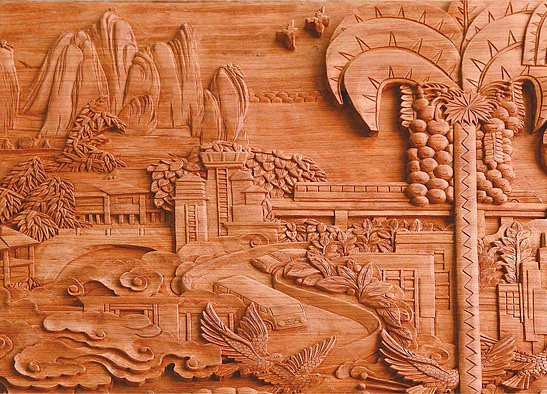

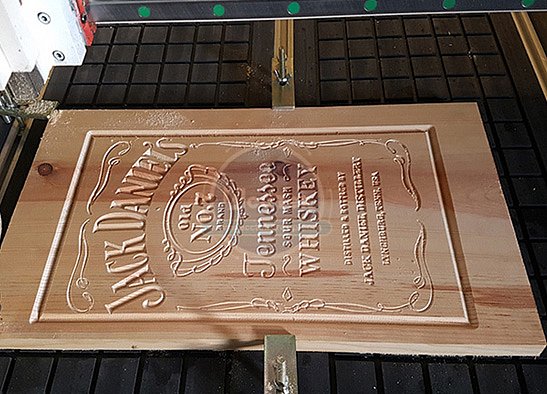

AKM1325 is an affordable CNC router, also known as 4x8 CNC router because of its worktable size of 4x8 feet. It is widely used in wood furniture industry and advertising industry. New designed overall sheet metal for all the four sides, looks more compact and neat. Here you can get the best products at the most favorable price.

Machine features:

3.2KW Water Cooling Spindle

Smooth body, not easy to rust; powerful and longer lifetime.

Water cooling, low noise. 0-24000 rpm, ER20 collets.

Mach3 Control System

We use Ethernet interface controller card, the program is installed on a computer connected to the control machine.

It is the most common software for CNC machines in the world, support Winxp Win7 Win10, doesn’t need driver installed.

Aluminum housing, shielding interference, stable and reliable.

HIWIN Guide Rails

Rail works with slider, drive the machine move.

High-speed and silent, with good bearing capacity.

Stepper Motor and Leadshine Driver

Without A/D conversion, the digital pulse signal can be directly converted into angular displacement.

Cheap and good performance, function is to drive the axis movement as parameter setting.

Fuling Inverter

This inverter has stable performance, rich combination of functions.

High-performance vector control technology, low-speed and high-torque output, good dynamic characteristics and super overload capacity.

Technical Parameters

Pre-Sales Service

Free Sample Cutting Service

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will cut it in our factory and make a video to show you the cutting process and results, or send you a sample to check the cutting quality.

Advancing Solution Design

According to the customer's product processing requirements, we can design unique solutions for customers to support higher manufacturing efficiency and better processing quality.

Custom Machine Design

Depending on the customer's application, we can modify our machines to achieve customer's convenience and high production efficiency.

After-Sales Service

• We will provide training videos and English user manuals for installation, operation, maintenance and troubleshooting for the laser machine, and will provide technical guidance via remote means, such as TeamViewer, email, phone, mobile, Whatsapp, Skype, 24/7 online chat, etc., when you encounter installation, operation or adjustment problems. (Recommended)

• You can come to our laser machine factory for training. We will provide professional guidance. Direct and effective face-to-face training. We have assembled machines, various tools and testing facilities here. Training time: 3 to 5 days (recommended)

• Our engineers will provide on-site guidance and training services in your local area. We need your assistance in visa procedures, prepayment of travel expenses, and accommodation before the dispatch and during the service. During the training, it is best to arrange a translator for our engineers (if they do not speak English).

Warranty Policy

• 3 years for the whole machine, 18 months for the laser, 12 months for the chiller, no warranty for the lens/mirror/nozzle.

• Long-term lifetime maintenance, the after-sales department will provide 24/7 English online support.

• Except for man-made damage, we are responsible for providing accessories free of charge during the warranty period.

• After the warranty period, the buyer only needs to pay for the actual repair costs.

• Certificate support: CE, FDA, SGS.

Small Package

Strong waterproof bottom made of plywood.

Spare parts for the laser source (separate plywood housing) and laser bed.

Corners are protected with foam and secured with protective film.

All covered with a strong, hard protective film.

Vacuum packed

Internal steel frame protectors

Plywood packaging and steel strapping outside to secure the box.

Packing is done using regular containers or flat rack containers.

Related Product Recommendation

Contact

+8613363699980

admin@guohonglaser.com