2024 Best Rated Fiber Laser Cutting Machine for Sale - 2000W

1 Cutting head advantages:

JG1325FC comes with a fiber laser cutting head for metal sheet cuts and a CO2 laser cutting head for non-metal cuts. It is a multipurpose laser cutter in the advertising industry.

2:Flatbed laser metal cutting machine with Raycus laser generator 1500W and 2000W and 3000W with long laser cutting service life of up to 100,000 hours and SWL brand 150W/300W CO2 laser tube.

3 Cost Saving. One machine can save over 30% electricity and 50% space; Effectively enhance productivity.

Advantages:

Compared with the Hybrid CO2 Laser Cutter

• Larger range of metal materials.

• Larger range of thickness on metal cutting.

• Higher precision due to ball screw transmission.

• Smoother cutting edges.

• The fiber laser and CO2 laser double heads cutter is an upgraded innovation edition of the standard mixed-head cutter.

• The feature of this combination leads the various of usage in all kinds of sheet metal industry.

Parameters:

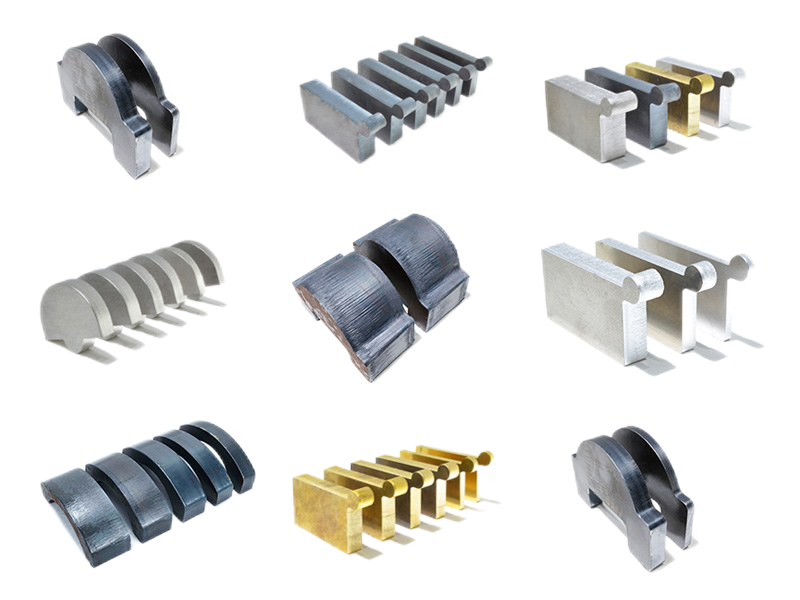

sample:

Pre-Sales Service

Free Sample Cutting Service

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will cut it in our factory and make a video to show you the cutting process and results, or send you a sample to check the cutting quality.

Advancing Solution Design

According to the customer's product processing requirements, we can design unique solutions for customers to support higher manufacturing efficiency and better processing quality.

Custom Machine Design

Depending on the customer's application, we can modify our machines to achieve customer's convenience and high production efficiency.

After-Sales Service

• We will provide training videos and English user manuals for installation, operation, maintenance and troubleshooting for the laser machine, and will provide technical guidance via remote means, such as TeamViewer, email, phone, mobile, Whatsapp, Skype, 24/7 online chat, etc., when you encounter installation, operation or adjustment problems. (Recommended)

• You can come to our laser machine factory for training. We will provide professional guidance. Direct and effective face-to-face training. We have assembled machines, various tools and testing facilities here. Training time: 3 to 5 days (recommended)

• Our engineers will provide on-site guidance and training services in your local area. We need your assistance in visa procedures, prepayment of travel expenses, and accommodation before the dispatch and during the service. During the training, it is best to arrange a translator for our engineers (if they do not speak English).

Warranty Policy

• 3 years for the whole machine, 18 months for the laser, 12 months for the chiller, no warranty for the lens/mirror/nozzle.

• Long-term lifetime maintenance, the after-sales department will provide 24/7 English online support.

• Except for man-made damage, we are responsible for providing accessories free of charge during the warranty period.

• After the warranty period, the buyer only needs to pay for the actual repair costs.

• Certificate support: CE, FDA, SGS.

Small Package

Strong waterproof bottom made of plywood.

Spare parts for the laser source (separate plywood housing) and laser bed.

Corners are protected with foam and secured with protective film.

All covered with a strong, hard protective film.

Vacuum packed

Internal steel frame protectors

Plywood packaging and steel strapping outside to secure the box.

Packing is done using regular containers or flat rack containers.

Related Product Recommendation

Contact

+8613363699980

admin@guohonglaser.com