Auto Tool Changer CNC Router

Standard ATC CNC Router, the system is upgraded to Syntec 60W-E, professionally used in high-end engraving machines, with higher anti-interference ability; using Taiwan Delta servo motor, the accuracy is higher, and the operation is more stable.

Machine features

9KW ATC air cooling spindle

9KW Chinese ATC air cooling spindle to ensure the machine can be vigorous cutting.

Smooth body, not easy to rust; powerful and longer lifetime.

Independent research and development, rational design.

Auto tool magazine

8pcs linear type auto tool changers, ISO30.

Don’t need to change tools manually when machine works, which saves a lot of time and greatly improves the efficiency of material processing.

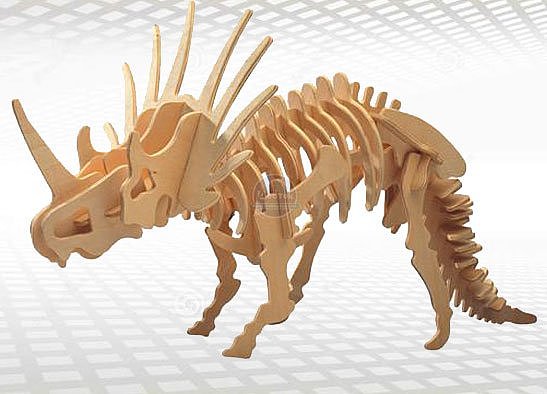

It is very suitable for complex and large-scale engraving processing.

Syntec controller

The system stability is very good, powerful functions, the operating software is simple and easy to learn, the man-machine operation is friendly.

Professionally applied to high-end cnc router machines, the anti-interference ability and control accuracy of the control system are superior to other types.

HIWIN Guide rails

Rail works with slider, drive the machine move, with good bearing capacity.

Taiwan Delta servo motor

Faster speed with signal feedback. Low heat radiation.

Run smoothly at ultra-low speed.

Reduce the vibration, avoid oscillation. Efficient torque enhancement.

5.5kw air vacuum pump

The air between the workpiece and the worktable surface is extracted to form a negative pressure, so as to achieve the purpose of fixing on the worktable.

The vacuum adsorption technology is applied to the woodworking cnc router to greatly improve the work efficiency.

3.0KW double bags dust collector

When the cnc router is working, the dust-proof brush on the spindle to control all the sawdust residues in a small range, and then debris is sucked into the vacuum cleaner.

It not only ensures the cleanliness of the working environment, but also benefits the health of the staff.

Parameters:

Pre-Sales Service

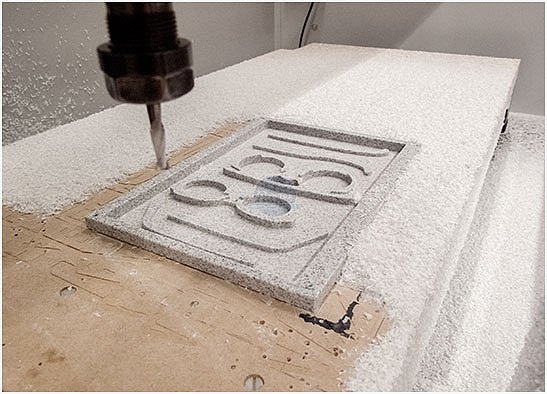

Free Sample Cutting Service

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will cut it in our factory and make a video to show you the cutting process and results, or send you a sample to check the cutting quality.

Advancing Solution Design

According to the customer's product processing requirements, we can design unique solutions for customers to support higher manufacturing efficiency and better processing quality.

Custom Machine Design

Depending on the customer's application, we can modify our machines to achieve customer's convenience and high production efficiency.

After-Sales Service

• We will provide training videos and English user manuals for installation, operation, maintenance and troubleshooting for the laser machine, and will provide technical guidance via remote means, such as TeamViewer, email, phone, mobile, Whatsapp, Skype, 24/7 online chat, etc., when you encounter installation, operation or adjustment problems. (Recommended)

• You can come to our laser machine factory for training. We will provide professional guidance. Direct and effective face-to-face training. We have assembled machines, various tools and testing facilities here. Training time: 3 to 5 days (recommended)

• Our engineers will provide on-site guidance and training services in your local area. We need your assistance in visa procedures, prepayment of travel expenses, and accommodation before the dispatch and during the service. During the training, it is best to arrange a translator for our engineers (if they do not speak English).

Warranty Policy

• 3 years for the whole machine, 18 months for the laser, 12 months for the chiller, no warranty for the lens/mirror/nozzle.

• Long-term lifetime maintenance, the after-sales department will provide 24/7 English online support.

• Except for man-made damage, we are responsible for providing accessories free of charge during the warranty period.

• After the warranty period, the buyer only needs to pay for the actual repair costs.

• Certificate support: CE, FDA, SGS.

Small Package

Strong waterproof bottom made of plywood.

Spare parts for the laser source (separate plywood housing) and laser bed.

Corners are protected with foam and secured with protective film.

All covered with a strong, hard protective film.

Vacuum packed

Internal steel frame protectors

Plywood packaging and steel strapping outside to secure the box.

Packing is done using regular containers or flat rack containers.

Related Product Recommendation

Contact

+8613363699980

admin@guohonglaser.com